As an avid coffee drinker, I wanted to reach a better understanding on where my coffee came from. What are the things that happen to coffee before it even reaches the store where I buy the beans? What was the flavor impact of some of these words and terminology I’ve seen on coffee bags?

A Sacramento-local coffee roaster and café, Insight Coffee, hosted a three-part series about coffee, each part held once per month. I decided to attend and learn about sourcing coffee and what happens to coffee before it reaches the warehouse of your local or national coffee roaster. How coffee is grown, where its grown, market dynamics, and processing.

Coffee processing is how coffee is prepared before arriving at the roaster. Surprisingly, there is a huge difference in flavor based on the process, discernible to even the casual coffee drinker.

Table of Contents

Five Fun Facts About Coffee

- Coffee is a fruit.

- Coffee trees can produce fruit for over 150 years.

- If coffee cherries float when placed in water, it means they are underripe.

- The fruit around the seed needs to be removed in every processing method before roasting.

- Roasting caramelizes the sugars inside of the seed – the amount of sugar impacts the sweetness.

How Coffee Beans Are Harvested and Picked

Coffee fruits must be picked at their peak ripeness. At any given time, a branch usually only has 20% of its fruit being ready for picking. This is a crucial reason why the human element will never be removed from speciality coffee producers and roasters. National coffees are more likely to use mechanical strippers to remove all of the fruit at once. Picking only the perfectly ripe coffee is called selective harvesting.

A veteran coffee picker is more likely to have half the amount of fruit than a newbie coffee picker in the same amount of time, due to experience of knowing how to select the top quality coffee. This is an industry problem, as pickers are often paid based on volume and not quality.

A ripe coffee fruit means more sugar has entered the seed – the part we roast. Roasting the coffee in effect caramelizes the sugar inside the coffee seed, or bean, and shapes some of the flavor .

The primary factors which affect flavor during the sourcing process of coffee are region of the world, altitude trees grow in, processing method, and ripeness level of the seed. Overall the size of the seed doesn’t impact taste, except for the peaberry, which is much sweeter.

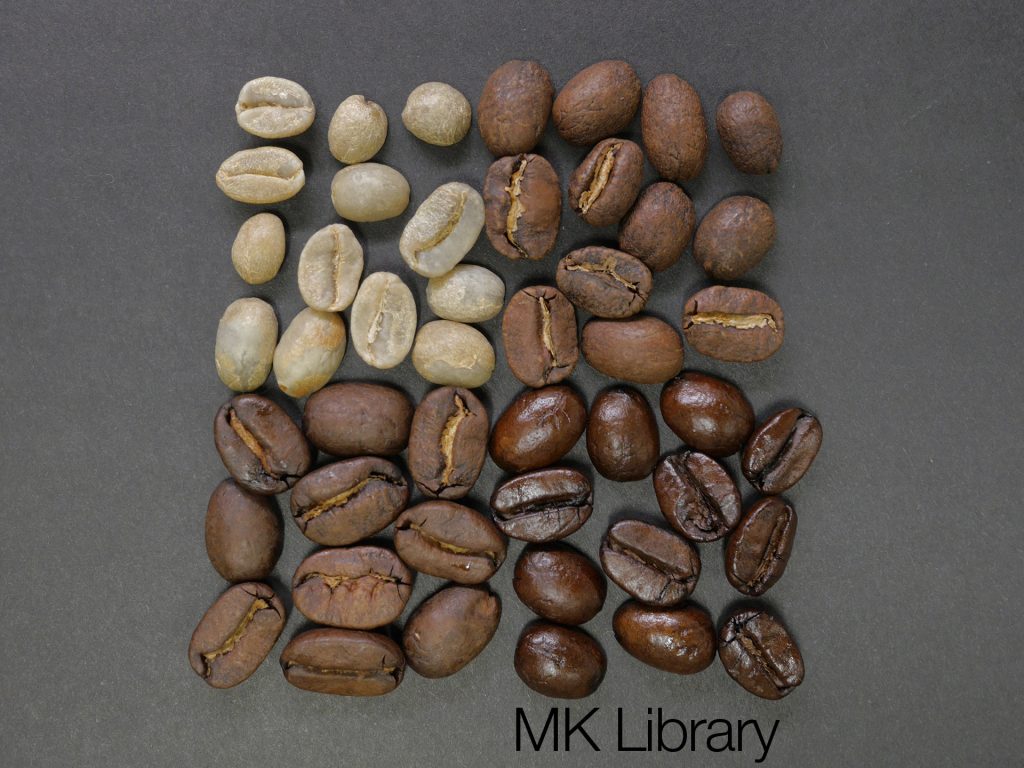

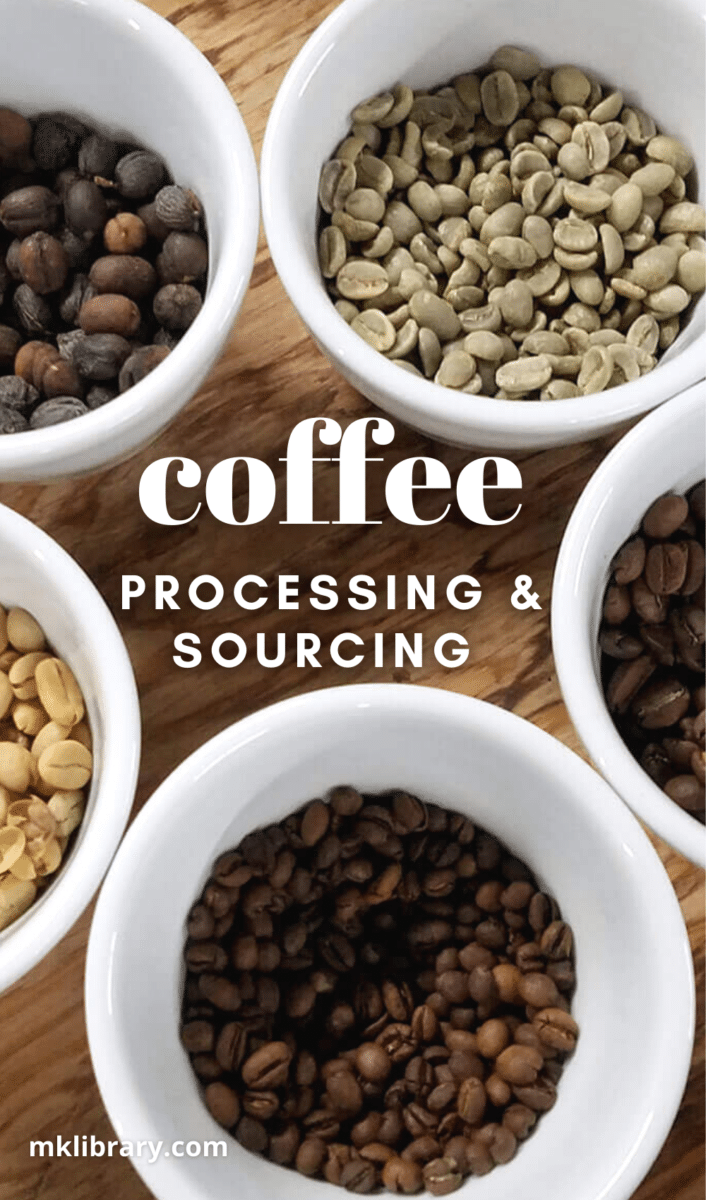

Processing Coffee

There are three methods to processing coffee. When tasting the same coffee, grown at the same location, picked at the same time, roasted the same way, but each batch processed differently, there is a marked difference. Is it good? Is it bad? This depends on your own personal palette.

- Washed Process – This removes the fruit by way of water and machines.

- Honey Process – This removes fruit without as much water as washing and requires much more manual labor.

- Natural Process – Fruit is laid out to dry in the sun, then removed in machines.

In each of these processes, there are a few universal steps which must happen.

Coffee beans are separated by size. This is important for the roaster to ensure continuity and consistency in the quality.

Three layers of the coffee fruit must be removed before it is sent to the roaster. The exocarp (skin), mesocarp (mucilage), and endocarp (parchment).

The coffee needs to be dried. An ideal moisture content in the coffee is 10 to 13%. According to one study (Martin et al. (2009)), the ideal drying includes intermittent drying, with 12 hours of 50º C heated air and 12 hours of rest. A second study (Isquierdo et al. (2011)), found that interrupting the drying process when the moisture content is 24% with a rest period of 2 to 12 days and later drying to 11% moisture content results in lower values of potassium leaching and electrical conductivity and, consequently, greater integrity of the cellular membrane system of the beans compared to coffee subjected to continuous drying to 11%. To sum it up, rushing the drying of beans results in a lower quality coffee. How much of a difference can the average person discern? I have no idea!

Washed Process Coffee

Washed coffee is the processed by placing the coffee in water for 12 to 24 hours and letting fermentation and nature to take its course. After the alloted time has passed, the coffee is moved to a second stage of washing where the outside fruit, or exocarp and mescocarp are removed through mechanical scrubbing machines. So why the fermentation? The mucilage of the coffee is insoluble to water and the fermentation allows for it to be more easily removed.

The coffee is then either dried in the air or in a machine, depending on the humidity of the facility. Drying is imperative to keep mold or fungus from growing on the coffee. If machine dried, the process is complete in a day. When layed out in the sun, it can take up to a week. Once dried, the next layer, the husk, is removed, with a similar process to sunflower seeds, which then reveals a green coffee bean, ready to be shipped and roasted.

Honey Process Coffee

The honey process is a method in which parts of the mucilage is left adhered to the coffee. The biggest difference between the honey process and washed process is the honey process skips the fermentation step. Unfortunately, this means the honey process is much more labor intensive for the coffee farms. Coffee must be manually turned as it dried, which results in a big sticky mess, thus the honey in the name. The “honey” is a very dark, almost black end of the spectrum, as the sugars caramelize onto the coffee bean.

The coffee is dried with parts of the mucilage and parchment together before the final layer is removed.

Dry or Natural Process Coffee

Natural processed coffee is dried with the entire fruit intact. Once the fruit is dry, machines are used to remove the fruit. The most notable attribute of dry processed coffee is it will keep the flavor of the coffee cherry itself.

Dry processing must be done in arid regions, as too much humidity means fungus and mold will take hold and ruin the production. Once dry, the fruit is removed using friction burr machines.

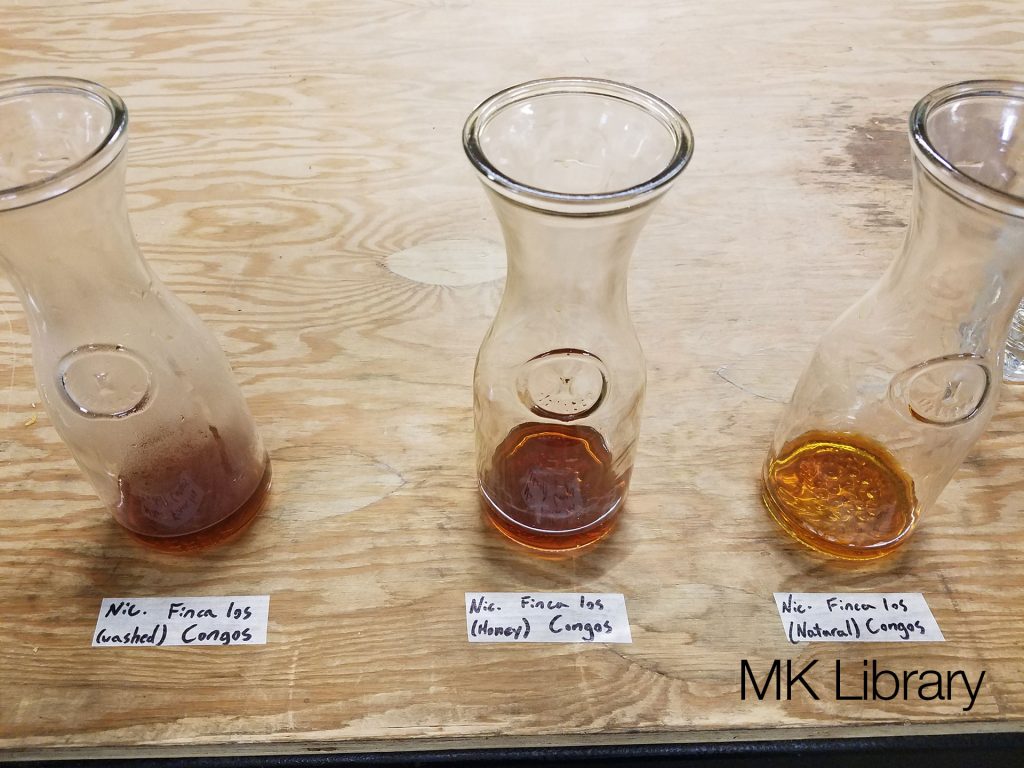

Coffee Processing Taste Comparison

One of the coffee farms Insight Coffee works with processed the exact same selective picking three different ways, as part of an educational experiment and to allow people to compare the tasting notes of each process. While you can’t taste the difference through this blog post, you can see the difference in color. I found the honey and natural processed coffee to taste much sweeter and similar in taste than the washed process coffee. Justin, our presenter, noted that last batch the Natural was fruitier, and this batch, the Honey was fruitier.

Ecological Impact of Coffee Processing and Water Usage

The amount of water used in processing depends strongly on the type of processing. Wet fully washed processing of the coffee cherries requires the most fresh water, dry processing the least. Sources indicate a wide range in water use. Recycling of water in the de-pulping process can drastically reduce the amount needed. With reuse and improved washing techniques, up to 1 to 6 m³ water per tonne of fresh coffee cherry is achievable; without reuse a consumption of up to 20 m³/tonne is possible.

| Process | Water use m³/tonne cherry | ||

|---|---|---|---|

| Semi-washed, wet processing | 3 | ||

| Fully washed, reuse of water | 4-6 | ||

| Fully washed and environmental processing (BECOLSUB) | 1-6 | ||

| Fully washed, recycling use of water | 4-8 | ||

| Semi wet and fully washed | 4-15 | ||

| Traditional, fully washed | 20 | ||

| Traditional, fully washed | 14-17 | ||

| Semi-washed, mechanical demucilage | 4 | ||

| Semi-washed, mechanical demucilage | 3.4 | ||

| Traditional, fully washed | 16 | ||

| Fully washed, reuse of water | 11 |

The fermented waste water from washed coffee is often improperly disposed of, which can be harmful to the surrounding environment.

- About the Author

- Latest Posts

I strive to paint vivid landscapes with my words, bringing the magic of far-off lands and enchanting aromas to life for my readers. Combine passion for exploration and the art of gastronomy in an unending ode to the senses. When I’m not traversing the globe, I find solace in the earth beneath my fingertips, tending to my garden and working on projects around my verdant oasis. MK Library serves as a beacon, guiding fellow travelers and homebodies alike to embrace sustainability, nurturing both our planet and our souls with purpose. Full Bio.

Absolutely fascinating.

Oh wow!! I thought there were coffee beans and coffee…in a tin 🙂 Honey process coffee, I would be very keen to try!!

Great informative post, thank you 🙂

I hope you get a chance to try honey processed from your local coffee shop! Be sure to ask and your barista would be delighted to share with you.

What a process! I literally had no idea. Awesome read, Mike!

Will, always happy to inform!

How interesting! It’s really cool to see more about what goes into your cup of coffee. I love my coffee but had never thought of these processes before!

Yeah, there is a lot that happens! I can appreciate the more expensive boutique cups of coffee so much more now.

What … no way! I had no idea about 99% of this post! This was so educational and entertaining! Great post.

Chantal, I’m elated to hear you found my writeup entertaining and educational!

I love learning about the coffee process. I love it!

Looks like this post was right up your ally! Thanks for stopping by.

Thank you so much for this!

Since when is coffee a fruit? *mind blown* I think this would be a great place to take students on a science field trip.

Yeah, I would love to visit a farm and get hands on!

Such an impressive post!

It is amazing how complicated the process is!

Yeah! This provides a nice foundation on where coffee starts. I haven’t even started talking about roasting the coffee yet!

These posts really set a standard.

This is a great example of stellar content. Very well done.

Thank you so much 🙂