Last Updated: July 9, 2025 by Michael Kahn. Published: July 13, 2020.

Sustainable paper products are more than just a trend-they’re a crucial part of building a greener future. As consumers increasingly seek out eco-friendly paper towels, recycled toilet paper, and compostable packaging, understanding what makes a paper product truly sustainable is essential. Factors like responsible forestry, renewable energy use, emissions reduction, recyclability, and social impact all play a role in shaping the environmental footprint of everyday items like Vanity Fair napkins, Brawny paper towels, and Angel Soft toilet paper.

FTC Disclosure: This post was originally sponsored by Georgia-Pacific in 2020 and has since been updated for newer information and accuracy. #GeorgiaPacificPartner

Georgia-Pacific, a leader in sustainable paper manufacturing, is advancing initiatives such as using biomass energy, expanding recyclable packaging options, and ensuring every tree harvested is regrown. These innovations are driving the shift toward eco-friendly paper products-and how you can make informed choices for a more sustainable home and planet.

Table of Contents

- The Lumberjack

- Paper Product Stats in the United States (2025 Updated and Verified)

- Single Use Products

- Single-Use Paper Products: Environmental Costs and Consumption Trends

- Recycling vs Composting Paper Products

- Wood Waste from Paper Product Manufacturing

- Sustainability on a Larger Scale

- Sourcing Paper Products

- Biodegradable Products Institute (BPI®)

- ECOLOGO® UL 175

- Forest Stewardship Council (FSC®)

- USDA BioPreferred® Program

- GREENGUARD Certification

- Sustainable Forestry Initiative (SFI)

- Programme for the Endorsement of Forest Certification (PEFC)

- Green Seal®

- UL Responsible Sourcing

- Wildlife Habitat Council (WHC)

- Tree-Free Paper Alternatives

- Paper vs. Digital: Carbon Footprint Comparison

- Innovative Materials and Paper Technology

Personal Disclosure:

Georgia-Pacific invited me to share their sustainability efforts in paper products and provided compensation for including their brand and messaging in this article. As part of my commitment to responsible content, I conducted independent research before featuring them.

I donated a portion of the proceeds from this sponsored post to Trees Atlanta, a nonprofit dedicated to protecting and expanding Atlanta’s urban forest. Georgia-Pacific is headquartered in Atlanta and is a significant supporter of Trees Atlanta, contributing both funding and resources to help further their environmental mission.

The Lumberjack

Years ago, I had the unique opportunity to spend a day with a retired lumberjack in Northern California. He was barrel-chested and soft-spoken, his laughter echoing through the forest as we navigated winding mountain roads.

Though well into his seventies or eighties, his energy and enthusiasm for the woods were infectious. The purpose of our outing was to explore some hidden hiking spots, but what I gained was a new perspective on forestry.

As we drove, he regaled me with stories from his decades in the logging industry, occasionally pausing to point out different tree species. “That there is a yellow pine,”he’d say, so often that I should have memorized it.

Early on, I assumed logging was simply a job for him, and I doubted he had much interest in conservation. But as the day went on, I was surprised to discover how deeply he cared about the forest’s health.

He distanced himself from those who practiced clear-cutting and neglectful logging. Instead, he spoke passionately about selective harvesting-how it supports forest regeneration, reduces wildfire risk, and protects rare species.

He shared stories of rescuing wildlife and monitoring the ecosystem, revealing a side of forestry that’s often overlooked: stewardship and sustainability.

That experience challenged my assumptions about the logging profession and left a lasting impression. Now, as I continue to research ways to make my own lifestyle more sustainable, I find myself asking similar questions about the products I use every day.

How sustainable are toilet paper and paper towels? What habits should I change to reduce my impact?

With Georgia-Pacific being one of the largest paper product manufacturers in the U.S.-their brands found in about 65% of American households and countless workplaces-it seemed like the perfect place to start my journey into the world of sustainable paper products.

Paper Product Stats in the United States (2025 Updated and Verified)

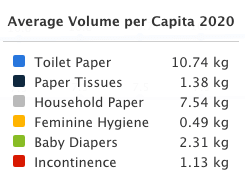

Per Capita Paper Use

- The average American uses approximately 700 pounds of paper annually, which is significantly higher than most other regions globally.

- U.S. per capita paper consumption remains among the highest in the world, though the gap is narrowing as other regions increase their usage.

Spending on Paper Products

- Household paper product prices have risen by 134% since 1997. In 2025, what cost $20 in 1997 now costs about $46.84.

- While exact annual spending per person varies, inflation and increased demand have driven up household paper product expenses in recent years.

Market Size and Growth

- The U.S. paper products market is valued at $330 billion in 2025 and is projected to reach $371 billion by 2030.

- The tissue paper segment alone is estimated at $96.24 billion in 2025, expected to grow at a 6.8% CAGR through 2032.

- The United States consumed approximately 58.3 million metric tons of paper and paperboard in 2023, making it the world’s second-largest consumer after China.

Paper Consumption Trends

- Despite high per capita use, total U.S. paper and paperboard consumption has declined by about 38% since 2000, reflecting digitalization and increased recycling.

- Office environments remain heavy users, with the average worker using 10,000 sheets of copy paper annually.

- 45% of office paper is discarded by the end of the day, highlighting significant waste and opportunities for reduction.

Forestry and Resource Management

- The U.S. uses an estimated 68–70 million trees annually for paper production.

- Sustainable forestry practices have improved, with more wood grown than harvested in many regions, though exact ratios fluctuate based on market and environmental factors.

Ownership and Stewardship

- 56% of U.S. forests are owned by individuals and companies, influencing how resources are managed and harvested.

- Private ownership plays a major role in sustainable forestry and conservation efforts.

Recycling and Sustainability

- In 2023, the U.S. paper recycling rate was 65–69%, among the highest for any material stream in the country.

- Nearly 60% more paper is recycled today compared to 1990, making paper recycling a major environmental success.

- Cardboard recycling rates are even higher, at 71–76%.

Additional Interesting Stats

- The U.S. is responsible for about 20% of global paper consumption, despite having less than 5% of the world’s population.

- The average business’s paper consumption increases by 22% per year, meaning usage can double in about 3.3 years if unchecked.

- More than 70% of businesses would fail within three weeks if they lost all paper records due to disaster, underscoring the ongoing reliance on paper in critical sectors.

Single Use Products

Single-Use Paper Products: Environmental Costs and Consumption Trends

Alongside positive improvements in sustainable forestry and manufacturing practices, single-use paper products remain a critical environmental challenge. While the paper industry has reduced greenhouse gas emissions by 21% since 2005 and improved water efficiency by 9% since 2010, consumer waste continues to undermine these gains.

Global paper consumption has increased by 400% over the past 40 years, with single-use items driving much of this growth. In the U.S. alone, discarded paper products account for 11.8% of municipal solid waste in landfills, while specific categories like napkins and plates contribute disproportionately to environmental strain.

Key Offenders in Single-Use Paper Waste

These are the most problematic single-use paper products in the U.S., their consumption rates, and associated environmental impacts.

| Paper Product | Annual U.S. Consumption | Key Environmental Impact |

|---|---|---|

| Coffee Cups | 50 billion | Requires ~20 million trees; 98% non-recyclable due to plastic lining |

| Paper Napkins | 693 billion (2,200 per person) | Contributes 28% of landfill waste from paper products; 1.5 billion lbs saved if reduced by 1/day |

| Paper Towels | 13 billion pounds | Uses 130 billion gallons of water annually; 17 trees per ton produced |

| Toilet Paper | 15 billion rolls | Consumes 660 million gallons of water yearly; 1.3 kWh energy per roll |

| Disposable Plates | 226 million users (2024) | $22.1B market by 2032; compostable variants reduce landfill mass by 60% |

Coffee Cups

The U.S. uses 50 billion paper coffee cups annually, requiring approximately 20 million trees. Despite their paper appearance, 98% contain polyethylene liners that clog recycling systems, sending 49 billion cups to landfills yearly.

Innovations like BASF’s recyclable cup coating-showcased in their 2024 pilot program-could reduce this waste, but adoption remains limited.

Paper Napkins

Americans use 2,200 napkins per person annually, totaling 693 billion units. If every U.S. resident used one fewer napkin daily, 1.5 billion pounds of waste could be diverted from landfills.

Restaurants account for 45% of this consumption, with cloth alternatives reducing water use by 39% in commercial laundries.

Paper Towels

Producing 13 billion pounds of paper towels annually drains 130 billion gallons of water and 221 million trees.

Offices exacerbate this issue: the average worker uses 3,000 towels yearly, while households spend $120–$180 annually on rolls.

Transitioning to 100% recycled towels could save 54,000 trees yearly.

Toilet Paper

The U.S. uses 15 billion toilet paper rolls annually, requiring 660 million gallons of water and 19.5 billion kWh of energy. While 65% of Americans prioritize recycled TP, only 28% of major brands use post-consumer materials.

Bamboo-based alternatives are growing at 25% annually but remain a niche market.

Disposable Plates

With 76% of North American market share, the U.S. consumed $21.7 billion worth of paper plates in 2024.

Heavy-duty plates-often coated with PFAS chemicals-account for 60% of sales, complicating composting efforts.

Compostable plate usage has doubled since 2020, driven by state-level bans on PFAS.

While companies like Georgia-Pacific invest in biomass energy and FSC-certified sourcing, consumer behavior remains essential to creaing a full circle sustainability intiative.

Replacing 50% of single-use cups with reusables could save 25 billion cups annually. Adopting recycled paper towels would reduce water use by 50% per ton produced.

Legislative measures, such as California’s 2025 Single-Use Packaging Law, aim to cut waste by 30% through recycled content mandates.

Recycling vs Composting Paper Products

The disposal of paper products like paper towels and cups remains a complex challenge in sustainability efforts. While recycling is often the first consideration, composting has emerged as a critical alternative for materials that cannot be reprocessed. This section examines the evolving landscape of paper waste management, supported by current data and municipal initiatives.

Most paper towels cannot be recycled due to their short cellulose fibers, which disintegrate during processing and contaminate recycling batches.

Contamination from food residues, oils, or cleaning chemicals further complicates recycling efforts.

- Clean, unbleached paper towels break down efficiently in compost systems, adding carbon-rich material to soil.

- Contaminated towels (e.g., those with grease or chemicals) should be landfilled to avoid introducing toxins into compost.

Studies show that diverting 50% of U.S. paper towels to compost could reduce methane emissions from landfills by 1.2 million metric tons annually-equivalent to removing 260,000 gasoline-powered cars from roads.

Cities across the U.S. have implemented specialized recycling programs to address poly-coated paper cups, which combine cellulose fibers with thin plastic liners.

Denver, Colorado’s program, launched in 2018, now recovers 22% of its 3,000 annual tons of cup waste, up from 10% in 2020. The city uses a dual-stream system where cups are pulped at Sustana’s facility, yielding 450 tons/day of de-inked fiber for new packaging.

Opting for 100% recycled paper products significantly reduces virgin fiber demand:

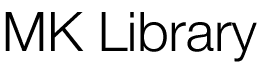

Georgia-Pacific’s Pacific Blue Basic™ towels contain 50–100% post-consumer recycled fiber, certified by Green Seal GS-1 for chlorine-free processing and water efficiency.

Their ARIA® bath tissue, relaunched in 2024, uses 100% recycled office paper fiber and paper-based packaging, diverting 12,000 tons/year from landfills.

If every U.S. household replaced one virgin fiber roll with a recycled alternative, 554,000 trees could be preserved annually-a projection based on 2006 USDA data that remains relevant given current consumption rates.

Georgia-Pacific has implemented closed-loop strategies to enhance sustainability:

Biomass energy: 70% of manufacturing power comes from renewable wood byproducts, reducing fossil fuel dependence.

Juno® technology: Recovers 85% of materials from commercial waste streams, including plastics and mixed paper.

Arbor Day Foundation partnership: Plants 3 trees for every 1 harvested in fire-damaged regions, with 1.2 million saplings planted in 2024 alone.

Educational campaigns, such as Northern Arizona University’s “These come from trees” stickers, have reduced paper towel use by 14% in campus facilities. Legislative measures are amplifying these efforts.

California’s 2025 Single-Use Packaging Law mandates 50% recycled content in paper products, projected to cut landfill waste by 30%.

The Paper Cup Alliance aims to achieve 90% U.S. cup recyclability by 2030 through mill partnerships and standardized labeling.

Wood Waste from Paper Product Manufacturing

Georgia-Pacific has established a closed-loop system that transforms wood waste into renewable energy, exemplifying circular economy principles in the paper industry. The company utilizes 100% of harvested trees, repurposing bark, wood residues, and pulping byproducts as biomass fuel for its manufacturing processes.

This approach not only minimizes waste but also reduces reliance on fossil fuels, aligning with broader sustainability goals.

Over 50% of Georgia-Pacific’s total energy demand is met through biomass, derived from organic byproducts.

The Alabama River Cellulose facility generates 90% of its operational energy from renewable sources, primarily biomass, while supplying excess power back to the grid.

21 Georgia-Pacific wood products facilities use biomass to produce steam and heat for manufacturing materials like plywood, reducing fossil fuel dependency.

The U.S. Environmental Protection Agency (EPA) classifies biomass as carbon-neutral because the CO₂ released during combustion is offset by the carbon sequestered by growing trees.

Since 2013, Georgia-Pacific has reduced its solid fossil fuel consumption by 72%, transitioning to biomass and natural gas, which has significantly lowered greenhouse gas (GHG) emissions across its operations.

Globally, the pulp and paper sector contributes less than 1% of total GHG emissions, a figure validated by a 2013 ECOFYS study.

Georgia-Pacific’s efforts have further reduced its carbon footprint through initiatives like the Naheola mill upgrade in Alabama, which replaced coal boilers with biomass systems, cutting particulate emissions and water consumption.

Georgia-Pacific’s Juno® Technology exemplifies innovation in waste management. Deployed in commercial settings, this system diverts 90% of processed waste from landfills by recovering recyclables and converting organic matter into energy.

At the Naheola facility alone, 88% of process waste (82,552 cubic yards annually) is repurposed for energy or reuse-equivalent to filling 25 Olympic-sized swimming pools. The Naheola mill earned the EPA’s 2019 ENERGY STAR® Project of the Year for emission reductions.

Sustainability on a Larger Scale

Since 2010, Georgia-Pacific has pioneered large-scale forest conservation through its Endangered Forest Mapping Initiative, leveraging advanced geospatial technologies to protect 6.6 million acres of high-conservation-value forests across 19 U.S. states.

Collaborating with the University of Georgia and environmental organizations like NatureServe, the company developed a GIS-based framework to identify ecologically critical areas, including habitats for endangered species such as the red-cockaded woodpecker and Louisiana black bear.

Partnering with Planet, GP uses monthly satellite imagery and automated algorithms to detect land-use changes in real time, ensuring no fiber is sourced from protected zones unless active management benefits species recovery.

A proprietary online platform grants suppliers instant access to updated endangered forest maps, fostering compliance with sustainable sourcing standards.

In designated areas, selective harvesting and replanting improve biodiversity. For example, controlled burns in longleaf pine ecosystems have boosted populations of the eastern indigo snake by 40% since 2019.

Georgia-Pacific adheres to a 1:1 reforestation minimum, replanting at least one tree for every harvested. For brands like Aria®, this ratio rises to 3:1, with 3.4 million seedlings planted since 2018 in fire-ravaged regions.

The company also operates as one of the world’s largest recyclers, processing 2.5 million tons of post-consumer fiber annually into products like the Pacific Blue Basic™ towel line, which uses 100% recycled content.

Georgia-Pacific has reduced its reliance on virgin fiber by 18% since 2015 while maintaining 65% household brand penetration.

Sourcing Paper Products

Photo: Exploring the trees around Bassi Falls.

When sourcing paper products, verifying sustainability claims through third-party certifications is critical for ensuring environmental responsibility. These certifications validate adherence to forest stewardship, manufacturing transparency, and end-of-life compostability. Georgia-Pacific exemplifies this approach through its compliance with multiple rigorous standards, as outlined below.

Biodegradable Products Institute (BPI®)

- Focus: Certifies compostability under ASTM D6400/D6868 standards, ensuring products break down in commercial facilities within 180 days without harmful residues.

- Georgia-Pacific Application: GP Pro® products meet BPI criteria, supporting circular systems in food service and hospitality sectors.

ECOLOGO® UL 175

- Focus: Evaluates sanitary paper products (toilet tissue, towels) for reduced chemical toxicity, sustainable fiber sourcing, and GHG emissions.

- Updates: Restricts carcinogens, allergens, and aquatic toxins while mandating chlorine-free processing.

- Georgia-Pacific Compliance: Aria® bath tissue and Sparkle® towels adhere to these health and environmental benchmarks.

Forest Stewardship Council (FSC®)

- Focus: Promotes biodiversity protection, indigenous rights, and responsible harvesting across 238 million hectares globally.

- Georgia-Pacific Integration: Select GP brands use FSC-certified fiber, particularly in packaging and office paper lines.

USDA BioPreferred® Program

- Focus: Encourages biobased materials while requiring innovative approaches in sourcing or manufacturing (e.g., agroforestry, closed-loop recycling).

- Georgia-Pacific Innovation: 94% plant-based packaging in Aria® products aligns with BioPreferred’s emphasis on renewable resources.

GREENGUARD Certification

- Tiers:

- Certified: VOC emissions ≤500 μg/m³.

- Gold: ≤220 μg/m³, ideal for schools/hospitals.

- Formaldehyde-Free: ≤5 µg/m²/hr emissions.

- Georgia-Pacific Use: Dispensary towels and healthcare products meet Gold standards for indoor air quality.

Sustainable Forestry Initiative (SFI)

- Standards:

- Forest Management: Climate-smart practices, fire resilience.

- Chain-of-Custody: Tracks fiber from certified forests.

- Georgia-Pacific Alignment: 72% reduction in fossil fuel use since 2013 via SFI-aligned biomass energy systems.

Programme for the Endorsement of Forest Certification (PEFC)

- Scope: Endorses national forestry standards (e.g., ATFS) across 325 million hectares, emphasizing smallholder inclusion.

- Georgia-Pacific Sourcing: Mixed-fiber products leverage PEFC-certified suppliers for global compliance.

Green Seal®

- Criteria: Lifecycle analysis of energy, water, and waste, with bans on PFAS and optical brighteners.

- Georgia-Pacific Leadership: Envision® napkins and cutlery meet GS-41 requirements for recycled content and low toxicity.

UL Responsible Sourcing

- Audit Areas: Ethical labor practices, conflict minerals, and deforestation risks in supply chains.

- Georgia-Pacific Transparency: Annual supplier scorecards track compliance with UL’s social and environmental metrics.

Wildlife Habitat Council (WHC)

- Conservation Focus: Certifies corporate land stewardship for endangered species and ecosystem restoration.

- Georgia-Pacific Initiative: Partnered with WHC to restore 8,000 acres of longleaf pine habitats for red-cockaded woodpeckers.

Emerging Standards and Consumer Guidance:

- LEED v4.1: SFI-certified wood contributes to credits in green building projects.

- Home Innovation NGBS Green: Prioritizes energy efficiency and low-emitting materials in construction.

- Safe Quality Food (SQF): While focused on food safety, SQF ensures hygienic paper packaging in food-contact applications.

Consumers should prioritize brands with multiple sustainability certifications, such as Georgia-Pacific’s Aria® line, which holds six or more credentials-including FSC® Recycled, ECOLOGO®, and USDA BioPreferred®-to demonstrate comprehensive environmental stewardship].

To validate these claims, buyers can cross-reference certifications through publicly accessible databases like the Forest Stewardship Council (fsc.org) and the Programme for the Endorsement of Forest Certification (pefc.org), which provide transparency into fiber sourcing and chain-of-custody practices.

Georgia-Pacific enhances accountability by publishing detailed annual sustainability reports, accessible via their corporate stewardship portal, which outline fiber origin maps, recycling rates, and progress toward emissions reduction targets.

This multilayered approach ensures that eco-conscious purchasing decisions align with verified, third-party standards.

Tree-Free Paper Alternatives

The paper industry is embracing innovative, tree-free materials to reduce deforestation and environmental impact. Three leading alternatives-hemp, bamboo, and bagasse-offer distinct advantages over traditional wood pulp.

Derived from industrial hemp, this hemp paper boasts an 85% cellulose content-nearly triple that of wood-resulting in stronger, longer-lasting paper ideal for archival documents and packaging.

Hemp grows to maturity in 90–120 days, requires minimal pesticides, and regenerates soil health, making it a carbon-negative crop. Historically used for banknotes and literature, modern applications include eco-friendly rolling papers and compostable packaging.

As the fastest-growing plant on Earth (up to 35 inches daily), bamboo provides a rapidly renewable fiber source. Its paper requires 30% less water than wood pulp and biodegrades completely without toxic residues.

Brands like Reel Paper leverage bamboo’s natural softness and strength for toilet paper, reducing reliance on virgin forests while maintaining durability.

A byproduct of sugarcane processing, bagasse paper repurposes 120 million metric tons of annual agricultural waste into sturdy food containers and packaging. Production emits 62% less CO₂ than wood pulp and consumes minimal chemicals, with compostable products diverting waste from landfills.

Cities like São Paulo now use bagasse for 60% of disposable tableware, cutting plastic use by 40%.

Paper vs. Digital: Carbon Footprint Comparison

The environmental impact of paper and digital media is often oversimplified. Below is a data-driven analysis based on global averages and lifecycle assessments, revealing nuanced trade-offs.

Key Metrics Compared

| Factor | Paper | Digital (Data Storage) |

|---|---|---|

| Carbon Footprint | 942 kg CO₂e per ton of paper (cradle-to-gate) | 40–1,000 kg CO₂e per TB/year |

| Replacement Threshold | N/A | 5,000+ pages read digitally to offset paper |

| E-Waste Impact | 65.9% U.S. recycling rate (2023) | 62M tons globally (2022), 22% recycled |

| Device Dependency | None | 300 kWh/year per TB stored (U.S. average) |

Scenario Analysis

1. Short-Term Use (e.g., Single-Use Documents)

- Paper: Preferable if recycled. A 10-page report (0.5 kg paper) emits 0.47 kg CO₂e vs. storing it digitally (1 MB ≈ 0.04 kg CO₂e/year).

- Digital: Only greener if accessed <5 times and deleted promptly.

2. Long-Term Storage (e.g., Books, Archives)

- Paper: A 300-page novel (1.5 kg) emits 1.4 kg CO₂e. If recycled, 65% is recovered.

- Digital: Storing the eBook (5 MB) for 10 years emits 2–50 kg CO₂e, depending on server efficiency.

3. High-Volume Consumption

- Paper: Reading 5,000 pages (25 kg paper) emits 23.5 kg CO₂e.

- Digital: Equivalent data (50 MB) emits 2 kg CO₂e/year but requires a device (e.g., tablet: 85 kg CO₂e to produce).

The environmental impact of paper and digital media varies significantly based on usage patterns, scale, and infrastructure. Below is a scenario-based analysis using data from peer-reviewed studies and industry reports (2018–2025), comparing carbon footprints across common use cases.

Scenario Analysis Table

| Scenario | Paper CO₂e | Digital CO₂e | Key Factors | Recommendations |

|---|---|---|---|---|

| Short-Term Use | 0.47 kg (10-page report, virgin paper) | 0.04 kg/year (1 MB stored in U.S. cloud) | – Paper emissions spike with virgin fiber use – Digital negligible if deleted quickly | Use recycled paper for single-use documents; delete digital files after short access |

| Long-Term Storage | 1.4 kg (300-page book, recycled) | 2–50 kg (5 MB stored for 10 years) | – Recycling cuts paper emissions by 38% – Server energy mix critical for digital | Archive on 100% recycled paper; choose renewable-powered cloud storage (e.g., Google) |

| High-Volume Consumption | 23.5 kg (5,000 pages read annually) | 2 kg/year (50 MB) + 85 kg (tablet production) | – Tablet lifespan critical: 5+ years reduces net emissions by 70% – Office paper waste averages 45% | Use shared devices for >3 years; adopt digital for frequently updated content |

| E-Waste Impact | 65.9% U.S. recycling rate (2023) | 62M tonnes globally (2022), 22% recycled | – 50 tonnes of mercury in undocumented e-waste – Paper recycling avoids 0.88 kg CO₂e/kg | Recycle devices via certified programs; prioritize repair and refurbishment |

| Renewable Energy Benefit | 72% fossil fuel reduction via biomass (Georgia-Pacific) | 64% carbon-free energy (Google Cloud, 2025) | – Biomachinery cuts paper emissions by 21% since 2005 – Solar/wind-powered data centers reduce digital footprint by 90% | Advocate for renewable energy contracts in both sectors |

By contextualizing these scenarios, users can make informed decisions that align with both operational needs and climate goals.

- Discarded electronics release toxins like mercury and lead, contaminating soil and water.

- Digital’s footprint drops 90% in regions with renewable-heavy grids (e.g., Iceland vs. coal-dependent India).

- A tablet used for 5+ years to replace 500 books reduces net emissions by 70%.

- Choose Paper When content is ephemeral, or recycled options are available.

- Choose Digital When information is accessed repeatedly, and devices are reused.

- Print essential documents on 100% recycled paper and use cloud storage powered by renewables (e.g., Google’s 64% carbon-free energy).

Life Cycle Assessment (LCA) of Paper Production

Recent Life Cycle Assessments (LCAs) reveal critical trade-offs between paper production methods, challenging assumptions about sustainability.

Recycled vs. Virgin Paper

Recycled paper reduces water use by 50% and energy consumption by 40% compared to virgin wood pulp. The deinking processes require 30% more chemicals, including hydrogen peroxide and sodium hydroxide, which contribute to aquatic toxicity.

While recycling avoids deforestation, methane emissions from landfilled paper offset 22% of carbon savings. For example, producing 1 ton of recycled paper emits 455 kg CO₂e vs. 942 kg CO₂e for virgin paper, but improper disposal negates 20% of this benefit.

Agricultural Residue Paper

Wheat straw paper, made from agricultural waste, reduces fossil fuel depletion by 62% compared to wood pulp. Its processing emits 40% more particulate matter due to higher lignin removal demands and chemical inputs like chlorine dioxide.

A 2023 study found straw-based pulp has a global warming potential of 2,299 kg CO₂e/ton-higher than recycled paper but lower than hemp or flax alternatives.

Biomass Energy and Carbon Neutrality

Mills using biomass (e.g., bark, pulping residues) meet 50–90% of energy needs renewably, cutting net emissions by 72% since 2005. Landfilled paper releases methane, which is 25x more potent than CO₂, offsetting 22% of biomass gains.

Georgia-Pacific’s Alabama facility avoids 150,000 tons of CO₂e annually via biomass but still contends with landfill-linked methane from consumer waste.

LCA Key Takeaways

- Material Sourcing: Virgin fiber requires 2x more water than recycled.

- Production: Straw pulping uses 35% less energy but 50% more chemicals.

- End-of-Life: Only 65% of U.S. paper is recycled; the rest emits methane in landfills.

Recommendations for Sustainable Choices:

- Prioritize Recycled Paper. Opt for brands with Green Seal® or ECOLOGO® certifications to ensure chemical management.

- Use of agricultural residues judiciously is ideal for packaging but should be avoided in regions with high PM2.5 pollution.

- Advocate for Biomethane Capture and support policies requiring landfills to convert methane to energy, as seen in Michigan.

By aligning choices with LCA insights, consumers and industries can mitigate trade-offs while advancing circular systems.

Innovative Materials and Paper Technology

The paper industry is developing innovations that redefine resource efficiency and environmental stewardship. These are three groundbreaking advancements driving this evolution.

Enzymatic Pulping

Traditional pulping consumes substantial energy to separate cellulose fibers from lignin. Enzymatic pulping, using bioengineered cellulases and hemicellulases, cuts refining energy by 35–40% by selectively breaking down lignin and hemicellulose bonds.

Trichoderma reesei cellulases modify fiber structures at lower temperatures, enabling mills like Georgia-Pacific’s Alabama River Cellulose facility to reduce fossil fuel use by 72%.

A 2024 study showed that pretreating poplar wood with xylanases decreased refining energy by 22% while improving paper strength. These enzymes also reduce chemical reliance-hydrogen peroxide use drops by 30% in bleaching stages.

Juno® Technology

Georgia-Pacific’s Juno® Technology tackles commercial waste contamination-a persistent recycling barrier. By sanitizing and processing waste in a pressurized steam vessel, Juno recovers 85% of materials from items like food-stained pizza boxes or coffee cups.

At its Toledo, Oregon facility, Juno diverts 82,552 cubic yards (25 Olympic pools) of waste annually, repurposing fibers into products like Pacific Blue Basic™ towels.

The system also converts food residues into biogas, offsetting 1,200 MWh/year of grid energy. Since 2020, Juno has expanded to airports and stadiums, increasing mixed-paper recycling capacity by 50%.

PFAS-Free Coatings

BASF’s ecovio® 70 PS14H6, a plant-based polymer, replaces PFAS in food packaging. Certified home-compostable (OK Compost Home), this coating decomposes within 180 days without microplastic residues.

Compared to traditional polyethylene linings, ecovio® reduces carbon footprints by 25% and enables 40% thinner coatings, saving 12,000 tons/year of raw material.

In 2024, Metpack adopted ecovio® for hot/cold cups, achieving 30% faster production speeds than PLA alternatives while meeting FDA food-contact standards.

Enzymes like laccases are being optimized for alkaline conditions to integrate into kraft pulping. If 50% of U.S. households adopted enzyme-refined toilet paper, annual energy savings could power 120,000 homes.

These technologies exemplify how industrial ingenuity and ecological responsibility can coexist, paving the way for a circular paper economy.

Pin This: